Welcome builders! This section is intended to provide answers to some of your questions about green, residential construction and building a Sunlight home. If you are new to green building and are interested in giving it a try, we can give you the information needed to be successful. Green residential construction is getting more popular every year and you will give yourself a professional advantage by getting into green home building and learning how to do it right. If you have been contacted by one of our customers about building their Sunlight home, please email or call us if you have further questions.

How We Work

Our primary service at Sunlight Homes is custom green home design, specializing in passive solar, structural insulated panel (SIP) homes. We design specifically for Murus polyurethane SIP panels and Pella windows. This is one of the reasons we sell our design work only as a part of our Component Package. Our kit includes the rough, structural shell of the home, made from custom fabricated polyurethane-filled SIPs, Pella windows, skylights and exterior doors. The contractor supplies all other materials and all labor needed to build and complete the home. Visit Murus.com for details and technical information on Murus SIPs.

How the Construction Works

Our customers contract directly with a local home builder of their choice to build their Sunlight home. We recommend that they choose someone who they can communicate with easily, who has received positive recommendations from previous customers and who they can trust.

If you have never built a SIP home before, don't worry! Most of our builders are new to SIP construction and many are new to green residential construction. Fortunately, our building system is straightforward and the learning curve is not steep. Our homes have been built across the country for over thirty years by builders new to SIPs and green home building and their inexperience has rarely been a problem.

SIP Information + Installation

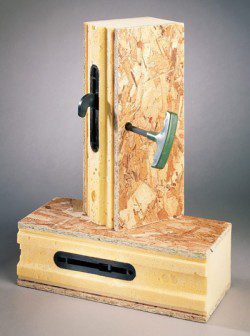

Murus panels have a cam-lock fastening system that makes joining the panels much easier. Cam-lock keys are provided to operate the hook that joins one panel to the next. The cam-locks are spaced every 2' along the vertical edge of each panel. Some builders find it easier to fasten several panels together while they are lying flat, then raise them into place as one unit.

Standard-sized panels are 4 feet wide and the height of the wall, although there are many custom-sized panels in every home. They are clearly labeled for easy identification. They come stacked and bundled in the order in which they will be used. When unloading, the panels are staged around the pad close to the place where they will be needed to avoid unnecessary hauling later. Panels are erected by number, following Murus' plans.

One critical element in the process is building a square and level foundation. Extra care should be taken to do this accurately. With a square and level foundation, the panels will fit together easily. During installation, the panels are glued, cam-locked and nailed to each other. Large panel screws connect the corner panels and the wall and roof panels together.

Really Important: Panels must be carefully braced with 2-bys until the structure is completely erected to avoid wind damage. Once the wall panels are erected and interior walls are framed, ridge beams are fit into factory-cut beam pockets and roof panels are set in place. We recommend a crane or other lifting device to set roof panels in place because they can be quite large and cumbersome.

Roof panels go up quickly with a couple workers on the roof fastening the panels together while the next panel is being hoisted into place.

Plumbing + Electrical

Sunlight homes are designed so that most of the plumbing and wiring is run in the crawl space or through interior frame walls. Plumbing and venting is still occasionally needed on some exterior SIP walls and in these cases the walls should be furred out with 2x material as required.

In most SIP homes, electrical wiring is run through conduits embedded in the SIP panels. The interior OSB sheathing must then be cut to provide space for switch and outlet boxes. We have found this method to be slow and inefficient and have developed a different solution. Electrical wiring on our SIP walls is done by installing 2"x2" furring strips vertically 16"oc on the interior surface of the SIPs. The furring strips stop several inches above the bottom of the wall, leaving a space to run wiring. The wiring is stapled directly to the panel, then up to the electrical boxes. Remodeling electrical boxes are used because they are shallow and do not cut into the panels. Once the wiring is run, drywall is applied to the furring strips. This method simplifies the electrical work, makes future remodeling much easier and meets all codes. We are happy to provide the electrical conduits in the panels if preferred, but we have had better success furring out the walls.

Cost Plus a Fixed Fee

We spent many years building our homes ourselves. After trying out many different fee structures with mixed success we decided to look for a better approach and discovered the cost-plus-a-fixed-fee method.

We used this method ourselves as builders and we now suggest this approach to all of our customers and their builders. We like how straight-forward, clear and fair it is and hope you do too.

The way this works is that the homeowner and the builder agree up front on a fixed fee that the builder will be paid for acting as the General Contractor on the project. Several factors are considered when determining the fee— the estimated cost of construction of the home, the size and complexity, the weather, the driving time to the project site, and the local building climate to name a few. We can help negotiate this fee if you would like.

The bottom line is that the builder needs to be paid a fair price for his work. This fixed fee covers it and then the home owner pays the builder's cost for all the labor and materials used in the home. This way the homeowner pays the true cost of the home and pays the builder a fair fee. The homeowner is saved the money a builder would have built in as "fudge factor" if the project runs smoothly and the builder knows exactly what he or she will make from the beginning. It's that simple.

To make this approach work, it's also important to have Open Books.

Open Books

To continue the simple, clean, straight forward approach to building, we also suggest an "open books" approach. When we build we use open books with our customers and have had rave reviews from them. We liked it too! Here is how we do it.

A new bank account is opened for every new project and all of the project's financial transactions move through this account. Both the builder and the customer have access to this account as well as to all of the invoices, so both parties know where every dollar goes.

Along with this, the customer gets the builder discounts on materials and builder pricing for labor. The builder is being paid a fixed fee and does not mark up anything more. As a result, the customer gets the discounts but also pays the extra if there are any problems during construction. In custom home building there are always a few surprises because, unlike tract homes, a custom home is like a prototype in that it has never been built before. We think that the advantage of having a clean, open arrangement that passes on the builder's costs and eliminates the contingency fees more than makes up for the occasional additional costs the customer has to pay to solve a problem during construction. These are, after all, part of the true costs of a custom home.

Let's Talk

We appreciate your interest in building a Sunlight home and are available to answer questions at any time before or during the process. If you are currently studying a set of our plans for an upcoming project, please contact us by phone or email. We would be happy to discuss the project with you in detail so that you can fully understand our green residential construction methods and how the project would work.

We know that we could not do our job without you and it's in our best interest as well as yours that our Sunlight residential construction project is a success for everyone. It's important that you are paid for your time and skills and we would like to talk to you further about how open bBooks and cost-plus-a-fixed-fee would work for you in this project. These approaches have been enormously successful to our builders and clients over the years because they are actually a more predictable, honest and "win/win" way to go.

We are here to help in any way we can to assist you in having a positive building experience. We are also happy to pass your name on to future customers who are building in your area since you will then be an experienced SIP builder experienced in green residential construction. Good communication is the key, and we look forward to hearing from you!